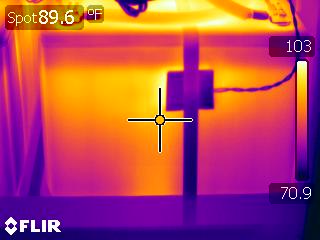

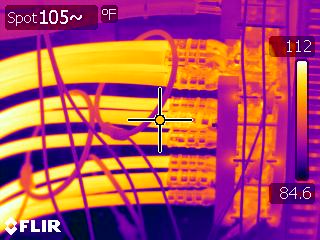

Thermographic testing allows for the inspection of a large amount of electrical equipment in a short time, versus a labor-intensive approach of physically inspecting electrical components. The thermographic inspection locates problems before they create an unscheduled outage, equipment damage, or fire. Facility engineers can avoid costly expenses by scheduling annual thermal imaging inspections.

Data Environments, Inc.’s certified thermographers inspect electrical equipment under normal loads and operating conditions. Scanning the electrical system in ‘real time’ helps identify electrical component problems. Certified thermography inspectors employ a non-invasive process that allows a facility to remain online and prevent interruption of operations.

The Data Environments, Inc. thermographic electrical inspection report is a management tool used to provide a condition inventory of the electrical system, and document electrical problems.

Thermal imaging should be used to inspect:

- Electrical utility substations and transformers

- Main electrical incoming services and transformers

- Main electrical switchboards and disconnects

- Uninterruptable electrical power supplies

- UPS battery systems

- Main electrical distribution panels and disconnects

- Remote power panels

- Power distribution units

- Bus ducts

- Generator controls and transfer switches

- Main I-Line electrical panel

- Circuit monitoring equipment

- Lighting and receptacle electrical panels

- Motor control centers

- Service electrical disconnects for motors